Fuel use

Using the average carbon footprint of winter wheat feed crops of 2,724 kg CO2e/ha, it was shown that moving from a plough-based to a direct drill cultivation system could cut fuel-use and reduce a crop’s carbon footprint by 9%. In addition, the fuel required at harvest to reduce grain moisture content significantly increased overall emissions. By harvesting grain at the right time to avoid any drying needs, carbon emissions could be reduced by a further 11%.

Nitrogen

Predictably, higher C footprints were associated with a strong reliance on artificial nitrogen (N). Growers of winter wheat feed crops with the highest GHG intensities were found to have applied on average 212 kg N/ha. Growers with the lowest GHG intensities tended to apply on average 165 kg N/ha, with no difference in average yield. When solely considering fertiliser manufacture emissions, this reduction in fertiliser use can reduce a field’s carbon footprint by 9%.

Dr Christina Baxter, ADAS consultant and YEN Zero network lead explains

“Artificial N fertiliser contributes over half of a wheat crop’s C footprint. However, this can be substantially reduced through improving nitrogen use efficiency through; measuring levels of mineral N in the soil, only applying what the crop needs, optimising application timings, and using urease and/or nitrification inhibitors where appropriate ”

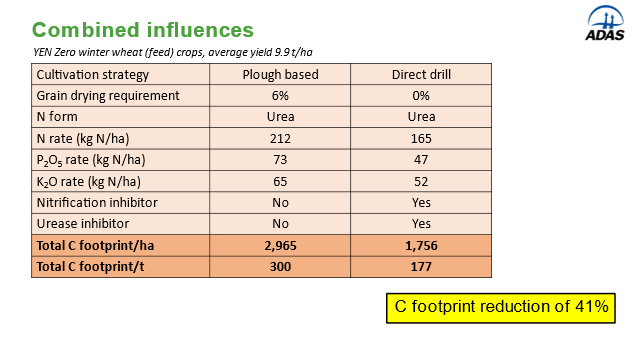

Combined Influences

Winter wheat (feed) crops, average yield 9.9t/Ha

Lincolnshire grower Colin Chappell who took part in the YEN Zero pilot year said

Some of my purchasers are now starting to ask for my carbon footprint; having joined YEN Zero, I have a definite answer per tonne that I can pass back to them. More than that though, through debate around said figures where knowledge exchange is key, we can work on ways to reduce the figures even further.

Fellow participant Suffolk grower Mark Harrington added

Taking part in YEN Zero enabled us to see not only where our carbon usage was high but also high carbon equals higher costs. If we are able to carry on recording inputs on the same fields throughout the whole rotation sequence over a number of years, then we will be able to benchmark each year against our own performance on the same soils etc as well as comparisons with other farms.

Dr Baxter summarised:

Being part of this collaborative endeavour across the whole supply chain, to uncover carbon reduction strategies that really work, has been so exciting. Thanks to our industry sponsors whose support has been vital for getting YEN Zero off the ground, and to the growers that took part. We’re now looking for more organisations and growers to join us to expand the network further, so if you’re keen to tackle your farm footprint, please do get involved

To find out more about YEN Zero and enquire about joining, please visit https://www.yen.adas.co.uk/projects/yen-zero